8″ x 12″ Modular Vacuum Chuck Kits

Preconfigured Modular Vacuum Chuck Kits with Multiple Vacuum Chucks – Quickly Set Up Custom Vacuum Chuck Table Sizes

Modular Vacuum Chuck Kits For Quick, Easy, Repeatable Set Up

8″ x 12″ Modular Vacuum Chuck Kits connect multiple Vacuum Chuck Pallets to quickly create different size and layout vacuum table size and workspaces.

Modular Vacuum Chucks are Precision Ground, Anodized Aluminum – manufactured in house.

Modular Vacuum Chuck Kits are available in four (4) preconfigured Kits that include one, two, three or four 8″ x 12″ Modular Vacuum Chucks and accessories.

Use one 8″ x 12″ Modular Vacuum Chuck, or connect multiple Vacuum Chucks to customize the size of the Vacuum Chuck needed.

Only one Vacuum Pump is required for multiple connected Vacuum Chucks

- The 8″ x 12″ Vacuum Chuck fits in a standard size milling vise,.

- Attach the Vise Block to the underside of the Vacuum Chuck to hold in a milling vise opening as small as 5”.

- Parts can be held on a magnetic chuck by attaching the Steel Vise Block.

- Numbered locations on the face of the Vacuum Chuck allow for quick and repeatable set up and consistent workpiece placement.

- Easy repeatable workpiece positioning between Vacuum Chuck Pallets is useful for high production; load one Vacuum Chuck off-line while another is being machined.

- A Vacuum Pump is needed to create the vacuum for workholding. Purchase an Air Venturi Vacuum Generator Pump or Portable Oil-Free Electric Vacuum Pump separately.

View complete product details.

View components of each Complete System.

View options and pricing.

Modular Vacuum Chuck Kits

Each Modular Vacuum Chuck Kit Includes 1, 2, 3 or 4 Vacuum Chuck(s) & a selection of the above accessories. Please review components for each Kit listed.

Each Single Pallet Vacuum Chuck Kit Includes:

Each Single Pallet Vacuum Chuck Kit Includes:

- 1 – Modular Vacuum Chuck 8″ x 12″ x 1.45″, Part No. 10275.

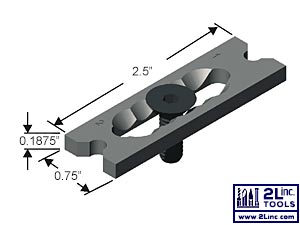

- 2 – Adjustable Edge Clamps 0.1875” Height, Part No. 10248.

- 2 – Adjustable Hex Workstops 0.1875” Height, Part No. 10247.

- 30 – Vacuum Sealing Plug Screws & O-Rings, Part No. 10246, 3 pkgs./10 ea.

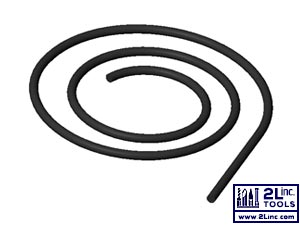

- 10 feet – 1/8″ Gasket Cord.

- 1 – Gasket Sheet: 8” x 12” x 0.125”, Part No. 10253.

- 1 – Vise Stop-Pin, Part No. 10252.

- 8 – Vacuum Plugs, Part No. 10254, 1 pkg./8 ea.

This Modular Vacuum Chuck Kit does not include a vacuum source. Review the below options.

- Air Venturi Vacuum Generator.

- Portable Oil Free Electric Vacuum Pump.

- A Complete Vacuum System including Vacuum Chuck, accessories, and choice of Air Venturi Vacuum Pump, or Portable Electric Vacuum Pump.

Replaceable Top Plates are available with varied configurations to protect the surface of your Vacuum Chuck.

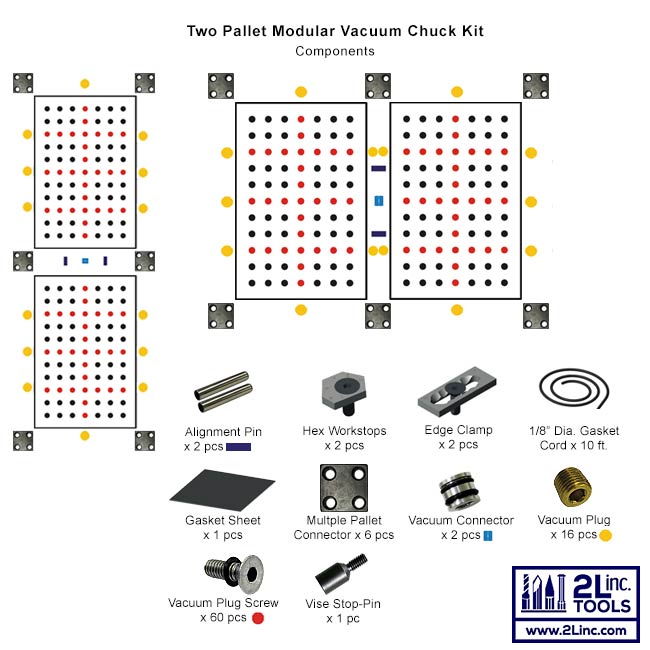

Each Two Pallet Vacuum Chuck Kit Includes:

Each Two Pallet Vacuum Chuck Kit Includes:

- 2 – Modular Vacuum Chucks (each 8″ x 12″ x 1.45″), Part No. 10275.

- 2 – Adjustable Edge Clamps 0.1875” Height, Part No. 10248.

- 2 – Adjustable Hex Workstops 0.1875” Height, Part No. 10247.

- 60 – Vacuum Sealing Plug Screws & O-Rings, Part No. 10246, 6 pkgs./10 ea.

- 10 feet – 1/8″ Gasket Cord (order more below).

- 1 – Gasket Sheet: 8” x 12” x 0.125”, Part No. 10253.

- 1 – Vise Stop-Pin, Part No. 10252.

- 16 – Vacuum Plugs, Part No. 10254, 2 pkgs./8 ea.

- 1 – Vacuum Connector, Part No. 10271.

- 2 – Alignment Pins, Part No. 10356, 1 pkg./2 ea.

- 6 – Multiple Pallet Connectors, Part No. 10258.

This Modular Vacuum Chuck Kit does not include a vacuum source. Review the below options.

- Air Venturi Vacuum Generator.

- Portable Oil Free Electric Vacuum Pump.

- A Complete Vacuum System including Vacuum Chuck, accessories, and choice of Air Venturi Vacuum Pump, or Portable Electric Vacuum Pump.

Replaceable Top Plates are available with varied configurations to protect the surface of your Vacuum Chuck.

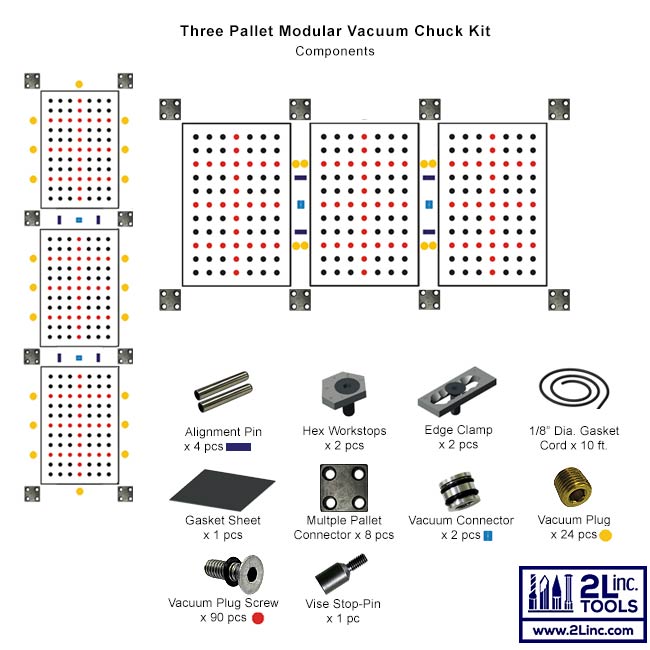

Each Three Pallet Vacuum Chuck Kit Includes:

Each Three Pallet Vacuum Chuck Kit Includes:

- 3 – Modular Vacuum Chucks (each 8″ x 12″ x 1.45″), Part No. 10275.

- 2 – Adjustable Edge Clamps 0.1875” Height, Part No. 10248.

- 2 – Adjustable Hex Workstops 0.1875” Height, Part No. 10247.

- 90 – Vacuum Sealing Plug Screws & O-Rings, Part No. 10246, 9 pkgs./10 ea.

- 10 feet – 1/8″ Gasket Cord (order more below).

- 1 – Gasket Sheet: 8″ x 12″ x 0.125”, Part No. 10253.

- 1 – Vise Stop-Pin, Part No. 10252.

- 24 – Vacuum Plugs, Part No. 10254, 3 pkgs./8 ea.

- 2 – Vacuum Connectors, Part No. 10271.

- 4 – Alignment Pins, Part No. 10356, 2 pkgs./2 ea.

- 8 – Multiple Pallet Connectors, Part No. 10258.

This Modular Vacuum Chuck Kit does not include a vacuum source. Review the below options.

- Air Venturi Vacuum Generator.

- Portable Oil Free Electric Vacuum Pump.

- A Complete Vacuum System including Vacuum Chuck, accessories, and choice of Air Venturi Vacuum Pump, or Portable Electric Vacuum Pump.

Replaceable Top Plates are available with varied configurations to protect the surface of your Vacuum Chuck.

Each Four Pallet Vacuum Chuck Kit Includes:

Each Four Pallet Vacuum Chuck Kit Includes:

- 4 – Modular Vacuum Chucks (each 8″ x 12″ x 1.45″), Part No. 10275.

- 2 – Adjustable Edge Clamps 0.1875” Height, Part No. 10248.

- 2 – Adjustable Hex Workstops 0.1875” Height, Part No. 10247.

- 120 – Vacuum Sealing Plug Screws & O-Rings, Part No. 10246, 12 pkgs./10 ea.

- 10 feet – 1/8″ Gasket Cord (order more below).

- 1 – Gasket Sheet: 8″ x 12″ x 0.125”, Part No. 10253.

- 1 – Vise Stop-Pin, Part No. 10252.

- 32 – Vacuum Plugs, Part No. 10254, 4 pkgs./8 ea.

- 4 – Vacuum Connectors, Part No. 10271.

- 8 – Alignment Pins, Part No. 10356, 4 pkgs./2 ea.

- 10 – Multiple Pallet Connectors, Part No. 10258.

This Modular Vacuum Chuck Kit does not include a vacuum source. Review the below options.

- Air Venturi Vacuum Generator.

- Portable Oil Free Electric Vacuum Pump.

- A Complete Vacuum System including Vacuum Chuck, accessories, and choice of Air Venturi Vacuum Pump, or Portable Electric Vacuum Pump.

Replaceable Top Plates are available with varied configurations to protect the surface of your Vacuum Chuck.

Complete Details:

Modular Vacuum Chuck Kits

- Use one Modular Vacuum Chuck Pallet or combine several to increase the workholding area.

- Preconfigured Vacuum Chuck Kits are available for ease of ordering which include one Vacuum Chuck, or Multiple Pallets of two, three or four Modular Vacuum Chucks and accessories.

- Use a Single 8″ x 12″ Vacuum Chuck, or connect multiple Vacuum Chucks to create a custom size and layout vacuum workspace quickly and easily.

- Additional Vacuum Chuck Pallets can be added to these kits to further increase the vacuum workholding area.

- Quickly create different size & layout Vacuum workspaces using the Modular 8″ x 12″ Vacuum Chucks.

- Vacuum holes can be used for vacuum, clamping, or locating the workpiece.

Gasket and Hold Down of Workpieces

- Quickly seal off the vacuum holding area by using 1/8” diameter Gasket Cord or 8” x 12” Gasket Sheet.

- Gasket Sheet can be trimmed to fit underneath specific workpieces.

Prototype Parts Quickly

- The 77 holes on the Vacuum Chuck top are threaded with accurate 1” spacing to allow placing low profile Adjustable Edge Clamps and Workstops anywhere on the Vacuum Pallet.

- This flexible design reduces set up times and eliminates the need for custom fixtures.

- There are 29 vacuum/clamp holes on the pallet top.

- Eliminates the need to create custom fixtures and allows easy prototyping of workpieces.

- Flexible configuration and set up allows you to prototype parts quickly.

Fits in a Standard Milling Vise

- Hold the Modular Vacuum Chuck in a standard milling vise or attach a Vise-Block for vise openings as small as 5”.

Repeatable For High Production

- Allows for quick and repeatable set up.

- Repeatable workpiece position between Pallets for high production. Load one Vacuum Chuck off-line while another is being machined.

- Numbered locations on the face of each Vacuum Chuck allow for repeatable and consistent workpiece placement.

- Quick Vacuum Gasket Cord placement allows easy workpiece size changes.

- Threaded Hole locations are labeled/numbered to allow documenting setups.

- The Vise Stop-Pin locates Pallet in the milling vise.

- Hex Workstops, Adjustable Edgeclamps, Side and End Workstops locate the workpiece consistently.

Drill Through Workpieces

- Replaceable Top Plates and the low slip Vacuum Gasket Sheets allow drilling through and machining around the outside of the workpieces without damage to the Vacuum Chuck.

Vacuum Source

- Only one Vacuum Pump is required when connecting multiple Vacuum Chucks together.

- An Air Venturi Vacuum Pump, or Portable Electric Vacuum Pump can be used to provide the Vacuum.

Hold Parts On A Magnetic Chuck

- Hold parts on a magnetic chuck by attaching the Steel Vise Block. Vise Block allows holding Aluminum, Plastic, and thin workpieces on a magnetic chuck for surface grinders.

Use as a Pallet for Fixturing Without the Vacuum

- Can be used as a Pallet for fixturing without the Vacuum by using low profile Adjustable Edge Clamps and Workstops.

- Low profile Adjustable Edge Clamps and Workstops reduce set up time and eliminate the need for custom fixtures.

- Adjustable Workstops and Edge Clamps can hold a wide range of height and size workpieces.

Vacuum Chuck Specs:

- Precision Ground Aluminum Modular Vacuum Chuck.

- 8″ x 12″ x 1.45″

- 77 threaded 1/4”- 20 holes.

- Threaded hole locations are labeled/numbered to allow documenting setups.

- 1.0” hole spacing for clamps allows for quick and accurate workpiece placement.

- 29 Vacuum Holes per Vacuum Chuck Pallet. One horizontal row of 11 vacuum holes and 3 vertical rows with an additional 6 vacuum holes each.

- Only one Vacuum Pump is necessary for multiple Vacuum Chucks.

- Connect multiple vacuum chucks with Vacuum Connector, which allows allows use of only one Vacuum Pump.

Hold Unique Size Parts & Hold Parts Securely:

Use a Hex Workstop and Edge Clamp to Securely Hold Various Size Parts, locate parts consistently.

- Adjustable Workstops and Edge Clamps can hold a wide range of height and size workpieces and can eliminate the need for custom fixtures.

- Tightening the flathead screw moves the Edge Clamp toward the workpiece, holding it securely in place.

- Low profile for maximum clearance.

- Reduce set up time and eliminate the need for custom fixtures.

- Numbered locations allow for repeatable set up.

- Black Oxide steel construction.

Side and End Workstops hold parts in place, reduce side pressure, locate parts consistantly.

- Side and End Workstops locate the workpiece consistently.

- Securely holds parts in place, minimizes workpiece movement if large amount of pressure is applied to the workpiece.

Protect the Vacuum Chuck Surface:

- Replaceable Top Plates and Gasket Sheets can be used to drill through workpieces and protect the surface of the Vacuum Chuck.

- Precision ground Replaceable Aluminum Top Plates are available to cover the surface of the Vacuum Chuck.

- Top Plates allow drilling through or machining around the outside of workpieces without damaging the vacuum chuck.

- Several configurations of Top Plates are available to hold unique size workpieces and protect the surface of the Vacuum Chucks.

- The low slip Vacuum Gasket Sheet allows drill through the workpieces without damage to the Vacuum Chuck and provides vacuum seal.

Vacuum Pump Selection:

These Modular Vacuum Chuck Kits do not include a Vacuum Pump.

- Use an Air Venturi Vacuum Generator Pump, Portable Electric Vacuum Pump, or Automatic Air Venturi Vacuum Pump System to provide the Vacuum.

- See all Vacuum Pumps here.

- You can also purchase a Complete 2L Vacuum System that includes Vacuum Chuck(s), accessories, and choice of an Air Venturi Vacuum Generator, Portable Oil-Free Electric Vacuum Pump, or Automatic Air Venturi Vacuum Pump System.

- See all Complete Vacuum Systems here.

Air Venturi Vacuum Generator Pumps

- Use of an Air Venturi Vacuum Pump is the most cost effective Vacuum Pump Option.

- The most popular Air Venturi Vacuum is the 1/4 NPT Vacuum Pump, Part No. 10033.

- Connecting shop air to the Air Venturi Vacuum Pump creates a vacuum.

- The Air Venturi is an excellent option when maching in shorter duration.

Automatic Portable Air Venturi Vacuum Pump

- This Automatic Vacuum Pump can be used with all of the 2L Modular Vacuum Chucks, Large Vacuum Chucks, and many other vacuum workholding systems.

- Creates a vacuum using standard shop air pressure and automatically turns on and off as required to maintain a set point.

- 4.5 SCFM Vacuum Pump, whic uses 5 SCFM of Compressed Air.

- 10.5 Gallon Steel Tank with Wheels, Handle, and a Bottom Drain.

- Maximum vacuum generated is 22″ HG – 26″ HG (10.8 psi – 12.8 psi).

- Only 70-80 psi air pressure is required to obtain the maximum vacuum.

- Automatic On/Off Adjustable Vacuum Switch reduces air usage and allows the Vacuum Pump to be left unattended for periods of time.

- 3/8″ NPT Vacuum Inlet Port.

- Large visible Inlet Filter with washable metal vacuum filter acts as a coolant trap to help keep contaminants from entering the tank.

- 110 VAC / 0.5A power connection.

- Vacuum Gauge with 2” diameter dial, Steel Case and Plastic Lens.

- Integrated air regulator with pressure gauge to adjust air pressure set point.

- Large No-Clog Silencer to produce a quiet 72db noise level.

- Ball valve drain on the tank bottom.

- Lighted On/Off switch allows visual indication that pump is on.

- If you are machining for longer cycles, the Portable Electric Vacuum Pump is an excellent option.

- It is independent Vacuum Pump, and using it will free up your shop air for other operations.

- 10.5 gallon steel tank with a 10 CFM vacuum system.

- 3/8″ NPT connection.

- Maintenance free 3/4 hp oil free/oil-less Vacuum Pump Motor.

- Vacuum Gauge.

- Automatic adjustable Vacuum Switch allows for auto on/off at a set vacuum.

- Large visible inlet filter allows for easy removal of coolant or debris.

110 VAC / 9.2A power connection. - Handle and Wheels for easy transport and moving of Vacuum Pump.

Modular Vacuum Chuck – All Available Accessories

Click Here to Order